Professional manufacturer of Roller Type Coal Briquette Machine

Phone/whatsapp: +86 13673361755

Phone/whatsapp: +86 13673361755

When selecting any production equipment, it is crucial to consider its performance and suitability, especially a briquetting machine. As one of the indispensable equipment in industrial production, the importance of the briquetting machine is self-evident. A suitable briquetting machine can greatly improve production efficiency and ensure product quality. Therefore, it is particularly important to choose the correct briquetting machine. It not only affects the efficiency in the production process, but is also directly related to the quality of the final product. Therefore, for any production-oriented enterprise, understanding and paying attention to the selection of briquetting machines is the key to improving enterprise productivity and ensuring product quality.

Russian customers come to our factory to visit and inspect our ball press machine

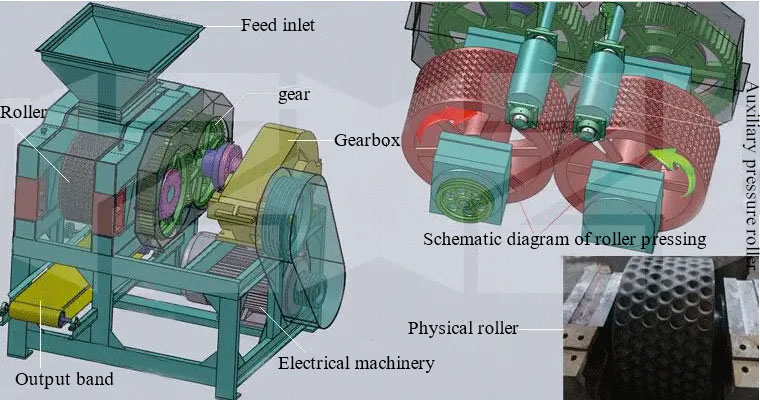

A briquetting machine is a device that uses physical pressure to press various powdery, granular or block materials into specific shapes. Its working principle is mainly to drive the rotation of the roller through the mechanical transmission system, so that the material is pressed between the two rollers, thereby achieving the purpose of pressing and forming. There are many types of ball press machines, which can be divided into three types: chain drive, gear drive and center drive according to the transmission mode. Among them, chain-driven briquetting machines have the advantages of simple structure and stable operation, and are suitable for small and medium-sized production enterprises; gear-driven briquetting machines are popular for their high transmission efficiency and low noise, and are mostly used in large production lines; center Transmission briquetting machines are widely used in chemical, building materials and other industries because of their compact structure and easy operation and maintenance. In general, different types of briquetting machines are suitable for different production environments and requirements. Choosing a suitable type is of great significance to improving production efficiency and ensuring product quality.

Working principle diagram of ball press machine

In assessing needs to determine the best model, we first focus on material characteristics. Different materials, their hardness, humidity, viscosity and other characteristics will affect the choice of briquetting machine. For example, for materials with higher hardness, we need to choose a briquetting machine with strong pressure; for materials with high humidity, we need to choose a briquetting machine that can effectively prevent the material from adhering. Secondly, output requirements are also an important reference factor for us to choose a briquetting machine. If our output requirements are higher, then we need to choose a larger briquetting machine with higher efficiency; if our output requirements are lower, then we can choose a small briquetting machine with slightly lower efficiency but lower cost. Finally, budget is also a factor we must consider. We need to choose the best briquetting machine for us based on our budget. If the budget is sufficient, we can buy a new briquetting machine with more powerful performance; if the budget is limited, we can choose a second-hand briquetting machine with a higher price. In general, evaluating needs to determine the best model is a process that comprehensively considers many factors. We need to choose the most suitable briquetting machine for us based on factors such as material characteristics, output requirements, and budget.

When choosing a briquetting machine, technical parameters and performance indicators are crucial. First of all, the size of pressure is a core consideration. It not only directly affects the quality of the press ball, but also determines which materials the machine can process. Secondly, the mold material is also something we need to consider. The material of the mold determines its durability and deformation under high pressure. Therefore, for different materials, we need to choose molds of different materials. For example, materials with higher hardness need to use molds made of high-strength materials such as carbide. . These technical parameters and performance indicators have a profound impact on our selection of the appropriate briquetting machine.

Russian client visits the ball press machine

While conducting an in-depth study of the briquetting machine market, we noticed significant differences between manufacturers and brands. Each manufacturer attracts potential customers with its unique technology and design, and comparison between brands has become a key issue. For example, some brands may lead in efficiency, while others have an edge in durability or customer service. Through meticulous market research, we are able to uncover these differences and help consumers and businesses make more informed decisions. This is not only related to product quality and performance, but may also affect long-term operating costs and return on investment. Therefore, whether you are new to the industry for the first time or a veteran looking to upgrade your existing equipment, it is crucial to have a thorough understanding of different briquetting machine brands and their product features.

When choosing a briquetting machine, we must comprehensively consider various factors, including equipment performance, stability, price, and after-sales service. We cannot just start from a single perspective, but need to consider comprehensively to achieve our goal, which is to find the most suitable ball press machine. The selection of this equipment is not only related to our production efficiency, but also directly affects the quality and cost of the product. Therefore, choosing wisely is crucial.

During the evaluation process, we should pay attention to the stability and performance of the equipment, because they are directly related to the continuous operation of the production line and the quality of the final product. In addition, price is also a factor that cannot be ignored, and we need to make a reasonable choice based on our budget. After-sales service is also something we must consider, because it can give us timely and effective help when equipment fails.

Overall, choosing the most suitable ball press should be based on a thorough evaluation and goal orientation, which is the key to making an informed decision. Only in this way can we ensure the smooth progress of the production process, while also ensuring product quality and cost control.

+86 13673361755

Shenglongjinzhonghuan Building, Zhongyuan District Zhengzhou City, Henan Province, China.