Overall

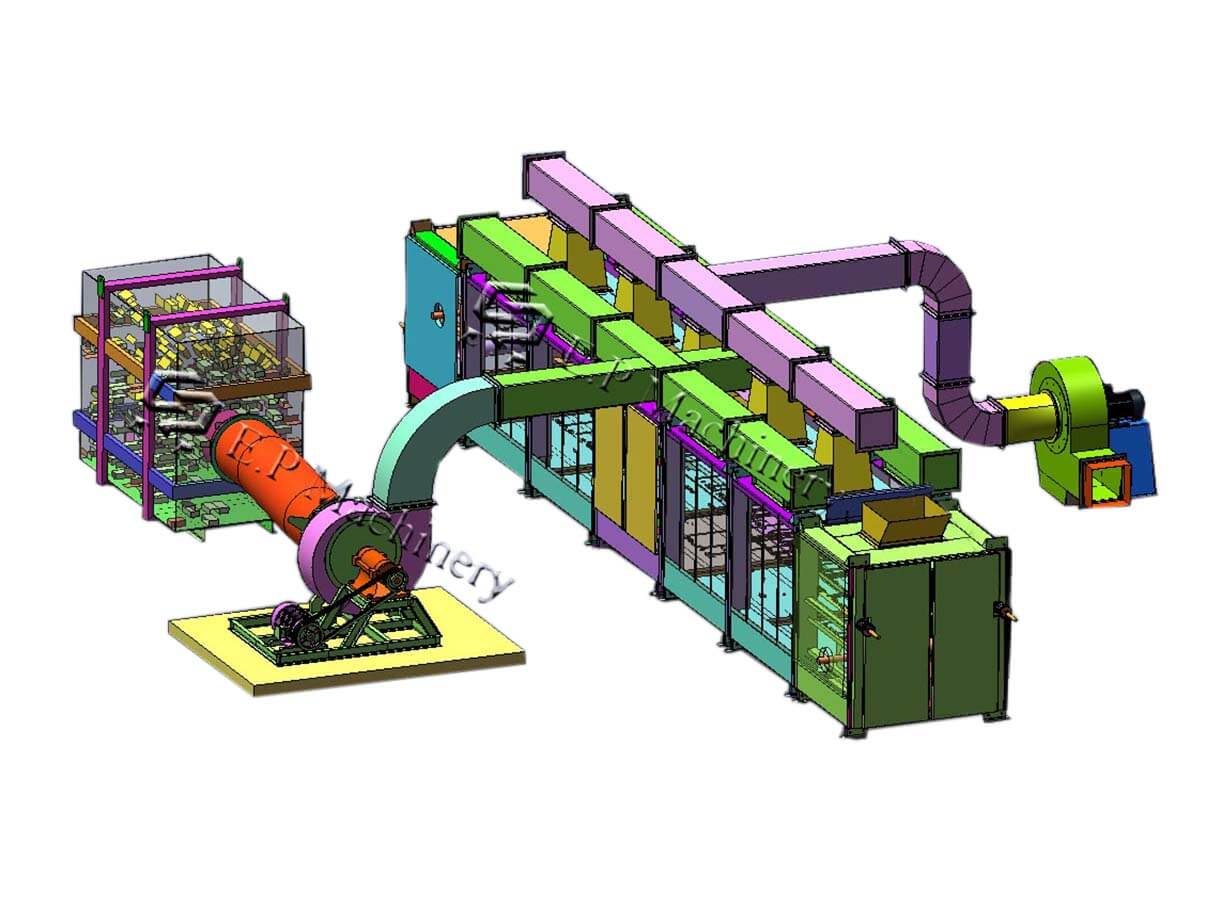

Chain plate dryer is the best efficient drying equipment, which is widely used in coal field, Metallurgical Industry, chemical field, etc, which has heating part, transmission part and dust-collecting part. The heating part includes furnace and pipes. The furnace supply heat through the pipes to the furnace body. The transmission part includes chain plates and frame, the briquettes are transported from the beginning of the top level to the next level, and finally to the end of the bottom level. The transmission speed can be adjusted by users’ needs. In the body of dryer, we adopt the chain plates to transfer the briquettes with the required speed, the transmission device will drive to move from the first level to the second level and the third level. During this moving period, the hot air will flow through the drying body and touch and mix with the briquettes completely, meanwhile, the steam will be exhausted from the wet vent, thus, the briquettes moisture will become dry and we get the drying function through the drying machine. The dust-collecting system includes fan, airlock, pipes and cyclone.

Features

Low breakage ratio, good drying efficiency, long service lifetime, wide application.

Function

The briquettes will be put on the chain plates by the conveyor evenly and continuously. Inside of the dryer, there are some heating units to supply the hot air around the box body to dry the briquettes. During the transportation in the dryer body, the briquettes humidity will be released to the lower ratio. It is mainly in coal briquette production line.

E.P will offer you the proposal of the whole coal briquette line, and give you our professional suggestion for drying part.

China plate dryer project in Brazil